Inventory is always on the move in a manufacturing business—raw materials arrive, finished goods get shipped out, and somewhere in between, your team has to assign costs to everything sitting on the shelf. The accounting method you choose will impact your reported profitability, tax obligations, and even your ability to catch problems early. These variances—whether in material costs, labor expenses, or overhead allocation—can reveal hidden issues in production and accounting, allowing manufacturers to improve pricing, cost control, and profitability.

Technology in Cost Reduction

Manufacturers can use the data generated by the system to evaluate the profitability of different products and decide which products to produce and which to discontinue. They can use this information to identify areas where the manufacturing process can be improved, leading to higher efficiency and productivity. Manufacturing accounting is a branch of accounting based on the financial management and control of manufacturing operations in an organization. It includes systematically recording, analyzing, and reporting financial data and transactions.

How to Manage Production Costs

For actual costing, the system calculates current costs and updates the Production Cost table. The system retrieves costs from the Item Cost table using the component’s inventory cost method. To support profitability management, you can track variances at the work center level. If you directed the system to perform item cost calculations at the work center level, then the system can display variances for each cost component of the different work centers that are used to produce an item.

Manufacturing Accounting Best Practices

You assign levels of detail (LODs) to control which accounts are subtotaled during the rollup process. You can use periods (the default), commas, or other user defined symbols to separate the components of the account number. Every business unit you define must have an object and, optionally, subsidiary accounts.

- Integrating or upgrading your accounting software, though important, runs the risk of increasing errors in your recorded business data.

- Manufacturing supplies, wages for non-production staff, and overheads like fuel or electricity can also all be considered direct costs.

- With numerous accounting methods and costing strategies that manufacturing businesses can use, it is always important to ensure that cash flow is maintained to avoid hiccups during production.

- By crediting Allowances on Purchases, companies can maintain accurate expense reporting while reflecting the true cost of materials acquired.

- Implementing manufacturing accounting systems, especially those designed for discrete manufacturing, is like automating the ship’s course, allowing for a more efficient journey.

key takeaways for understanding process costing

Process costing suits manufacturers producing large quantities of identical items, as it calculates costs for each production stage rather than individual units. By allocating direct and indirect costs to each process, businesses can determine per-unit expenses more efficiently. These classifications help businesses allocate resources more effectively and identify inefficiencies. Companies can better control production costs by organizing expenses with a tailored chart of accounts.

Costing Methods for Inventory

You should consult your own legal, tax or accounting advisors before engaging in any transaction. The content on this website is provided “as is;” no representations are made that the content is error-free. Fixed labour costs could include contractors, technicians, and maintenance staff with set jobs to do with set fees.

- It requires adjustments for work-in-progress (WIP), application of overhead, and reconciliation of inventory balances.

- Accounting for manufacturing companies becomes significantly more efficient and beneficial when these best practices are followed.

- Automated internal controls are great at continuously tracking transactions and activities and flagging anomalies for further investigation.

- One of the most powerful applications of manufacturing accounting is analyzing profitability at the product and customer level.

- Understanding manufacturing costing is like assembling a complex machine; every part must fit perfectly to work efficiently.

- Navigating the manufacturing landscape without accounting efficiency is like sailing a ship through…

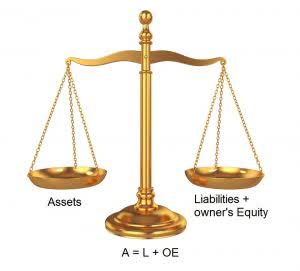

What is manufacturing cost accounting?

You can perform the update interactively when you record the hours and quantities, or you can run the Work Order Hours and Quantities Update program (R31422). The update uses the hours and quantities that you recorded for work order operations from the Work Order Time Transactions table to update the corresponding fields in the Work Order Routing table. The transaction data is then available for use by the Manufacturing Accounting Journal Entries program (R31802A) for work in process or completions. These values are updated when you report labor and machine hours in the Work Order Time Entry program and run the Hours and Quantities Update program (R31422). When you attach the parts list and routing either interactively or in batch, the system compares manufacturing accounting process the frozen standard costs and the current costs, and updates the Production Cost table. The frozen standard costs come from the Item Cost Component Add-Ons table; they are based on the original bill of material and routing.

Lifecycle Costing

We handle the hard part of finding the right tax professional by matching you with a Pro who has the right experience to meet your unique needs and will manage your bookkeeping and file taxes for you. Contract manufacturing is the outsourcing of certain manufacturing jobs to another (third-party) company. For example, a smartphone manufacturer might outsource the audio components to a speaker manufacturing specialist. For example, if your beginning inventory cost is £50,000, your COGM is £25,000 and your ending inventory is £20,000, your cost of goods sold is £55,000. Manufacturing accountants also keep how is sales tax calculated an eye on other important areas of expenditure to ensure the budget is followed throughout the financial year. This depends on whether the labour requirements of a particular job change as you add more volume.

Large-Scale Production

This KPI highlights cost anomalies, such as rising material prices, and ensures accurate tracking of production expenses. Manufacturers must navigate complex regulations in manufacturing accounting in the Philippines, from GAAP standards to local tax requirements. Compliance includes adhering to rules on accrual-basis accounting and inventory capitalization. It is particularly vital because it involves an upfront investment in production Oil And Gas Accounting before sales occur. Adhering to this principle ensures financial accuracy and compliance with accounting standards.

The Complete Guide to Information Lifecycle Management (ILM) for Modern Businesses

Understanding these cost components allows manufacturers to accurately determine product costs, set appropriate pricing, and identify opportunities for cost reduction. It also helps distinguish between period costs (general operating expenses) and product costs (those incorporated into inventory valuation), which impacts both financial reporting and tax obligations. The primary cost components in manufacturing are direct materials, direct labor, and manufacturing overhead.

Leave a Reply